Our Manufacturing

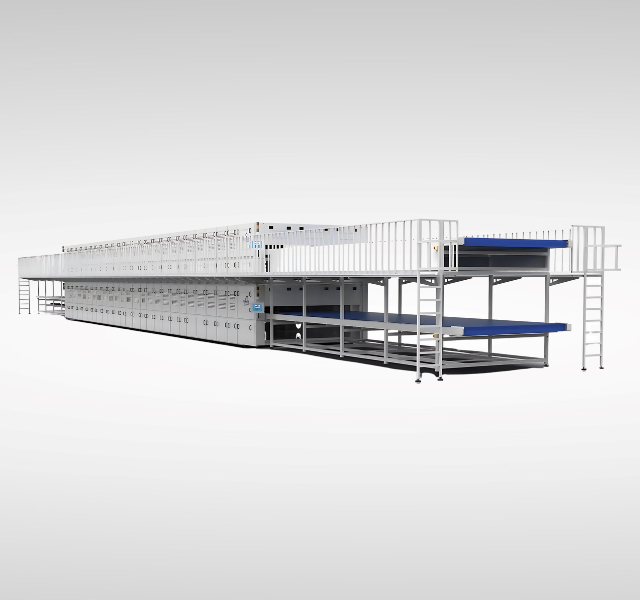

We’re India’s first fully automated BIPV line, with an annual capacity of 2 million sqm. Located in our IGBC Green certified facility in Halol, Gujarat, our BIPV modules are custom-crafted for architects, developers, and homeowners. Unlike traditional solar panels, our modules seamlessly integrate into buildings, combining aesthetics with structural integrity through advanced material engineering and strict adherence to standards.

A state of the art manufacturing facility at Halol, Gujarat, with an annual capacity of 300MWp of conventional Solar and BIPV modules. India’s first fully automatic manufacturing line for customised BIPV modules, tailor-made for Architects, Developers, and Homeowners. An IGBC Green certified factory setting high standards in sustainability for manufacturing high-quality sustainable products.

We pride ourselves on delivering high-quality solar panels through a meticulous manufacturing process. Each stage is designed to ensure durability, efficiency, and aesthetic appeal.

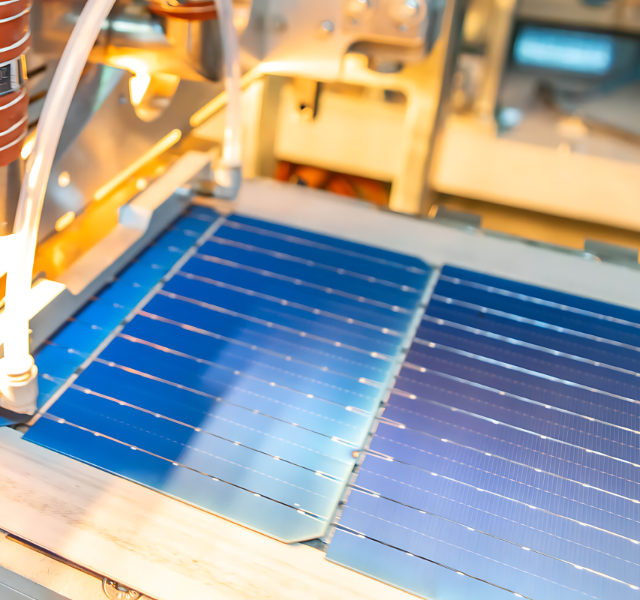

Cell sorting and cutting

Our Stringers are compatible with 210 x 105 mm 18BB, 183.75 x 91.1 mm 16BB TopCon and 210 18BB HJT Solar cells.

Cells are sorted based on electrical characteristics like current and voltage to ensure uniform performance across the module.

Glass loading

NRC Solar glass is loaded onto the production line, serving as the front protective layer for standard modules. Ultra clear solar glass with enhanced strength, designed to endure harsh weather conditions and environmental elements, ensuring the durability of solar panels and highest sunlight transmission.

For BIPV, tempered glass of various thicknesses up to 12mm may be used depending on design and building integration needs.

PV Layer (Cell Stringing and Layup)

High-efficiency photovoltaic cells are meticulously arranged and soldered into strings using automated machinery. These strings are then laid out on the tempered glass, ensuring optimal alignment for maximum energy capture. The cells are interconnected with precision to facilitate efficient electrical flow.

In BIPV modules, cell placement may be customized to allow transparency, patterns, or spacing for design considerations.

Lamination

Our Laminator is customised with dual chamber technique and treatment for laminating BIPV modules. The layered structure—glass, encapsulant, cell strings, backsheet or second glass—is laminated under heat and vacuum to bond all layers and remove air.

BIPV laminates often use dual-glass construction to meet architectural durability and aesthetics.

Junction Box Placement (JB)

A junction box is affixed to the rear of the laminated panel. This component houses the electrical connections and bypass diodes, which are crucial for maintaining performance when the panel is partially shaded. The junction box is sealed with high-quality adhesives to ensure it is waterproof and dustproof, meeting IP68 standards.

For BIPV, junction box positioning may be adjusted for concealed wiring or façade integration.

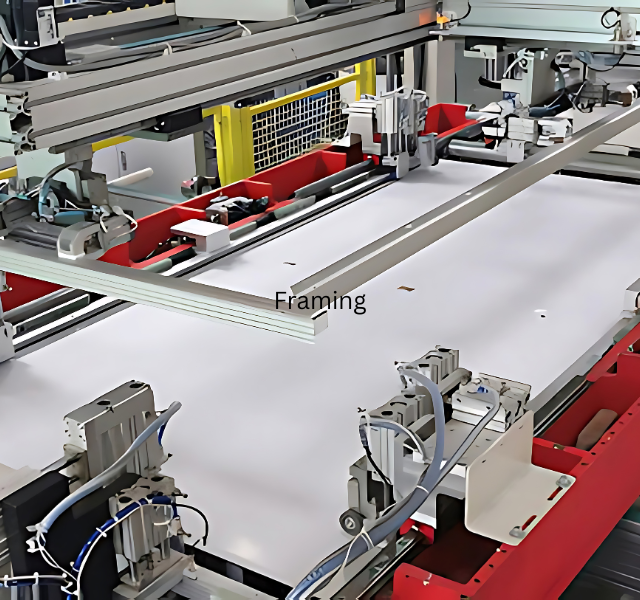

Framing

Standard modules receive aluminum frames for mechanical strength and mounting compatibility.

For full black modules, we use anodized AL frames.

In BIPV, frameless designs are common, or custom framing is used to match building façades or roof tiles.

Curing

Post junction box installation, the panels undergo a curing process in a controlled environment. This step ensures that all adhesives and sealants fully set, solidifying the structural integrity of the panel and enhancing its longevity.

The curing process is often adapted in BIPV modules to accommodate varying materials or thicker glass layers.

Testing

Modules undergo electrical performance tests (EL, IV curve, insulation resistance) to verify output and detect defects.

BIPV modules may also undergo additional tests for building safety standards like fire resistance and load-bearing.

Labelling and Packing

After rigorous quality checks, including electrical performance testing and visual inspections, each module is labelled with traceability data such as serial number, wattage, and certification marks.

Packaging is tailored to prevent damage during transport; for BIPV modules, special handling is often required due to non-standard shapes or glass types.